Insights

Founded in the year 1945, Kryolan Cosmetics is a leading global manufacturer of professional makeup products, trusted by artists in film, theater, television, and beauty industries worldwide.

The lack of centralized visibility, manual tracking, and inefficiencies across retail, warehouse, and production raised the need for an advanced ERP solution that enhances productivity, accuracy, and profitability.

Read the LOGIC ERP x Kryolan | Cosmetic ERP Software Implementation Case Study to discover how we helped them overcome challenges with a unified ERP software solution that streamlined retail, warehouse, and production operations, empowering the brand with real-time visibility, quality control, and data-driven decision-making.

About Kryolan

For over eight decades, Kryolan has been redefining makeup excellence through scientific innovation, premium formulations, and uncompromising quality standards.

With a strong presence in 90+ countries, Kryolan’s reach extends across continents, empowering makeup professionals with high-performance products crafted for creativity and precision.

In India, Kryolan has established its operational base with exclusive retail outlets and state-of-the-art production facilities. The Chennai branch serves as a strategic hub for South India, overseeing retail, distribution, and in-house manufacturing along with quality control for select product lines.

From professional makeup studios to beauty academies and cosmetic retailers, Kryolan continues to inspire confidence, creativity, and color, everywhere artistry meets innovation.

Location

In India, Kryolan operates a centralized facility in Chennai, which houses their:

- Head Office (HO)

- Warehouse (WH)

- Manufacturing/Production Unit

In addition, Kryolan has 9 exclusive retail stores located across three major metro cities:

- Bangalore

- Chennai

- Mumbai

These stores serve both B2C and B2B customers, including makeup professionals, beauty institutes, and cosmetic retailers.

Challenges Faced by Kryolan Professional Make-up before LOGIC ERP Implementation

Due to the lack of advanced cosmetics ERP software solutions, Kryolan Professional Make-up team faced several operational challenges that restricted growth and efficiency. Check out the list of challenges faced by Kryolan Professional Makeup before LOGIC ERP implementation:

Lack of Centralized Visibility Across Retail, Warehouse, and Production Units

Cosmetic and skincare brands often operate multiple locations, from manufacturing plants to retail outlets and warehouses. Without a centralized ERP system, gaining real-time visibility across these operations becomes nearly impossible, leading to delays in decision-making and stock mismatches.

Manual Tracking of Manufacturing and Batch Processes

The beauty and personal care industry relies heavily on batch production and formulation control. Manual tracking of production stages, batch reconciliation, and quality parameters often leads to errors, compliance issues, and reduced efficiency.

Inability to Accurately Track Raw Material Usage and Wastage

For cosmetics and skincare manufacturers, precise tracking of raw materials like essential oils, pigments, and chemicals is important. Manual processes make it difficult to measure consumption accurately, resulting in material wastage, cost overruns, and poor inventory control.

No Integrated System for Quality Control at Different Stages

Maintaining consistent product quality is non-negotiable in the beauty industry. However, without an integrated Quality Control (QC) module, monitoring parameters at each stage from raw material inspection to final packaging, becomes challenging, increasing the risk of non-compliance.

Difficulty in Managing Sales, Stock Movements, and Profitability

Cosmetic retailers and distributors often face challenges in tracking sales performance, stock levels, and product profitability across multiple channels. A lack of consolidated reporting makes it hard to analyze market demand, plan production, and forecast revenue effectively.

Fragmented Systems Leading to Inefficient Workflows

When different departments like production, inventory and sales operate on separate systems, it creates data silos. These workflows reduce collaboration, slow down operations, and prevent management from gaining a unified view of business performance.

How Did LOGIC ERP Help Kryolan With ERP Software Implementation?

LOGIC ERP, understanding Kryolan’s operational challenges, implemented an advanced Cosmetics and Beauty ERP software solution to meet their retail, manufacturing, and distribution needs. With LOGIC ERP’s industry-specific modules, Kryolan was able to streamline its inventory management, production planning, batch tracking, quality control, and retail operations under one unified system. The implementation enabled real-time visibility across warehouses, production units, and retail outlets, improving accuracy in raw material tracking, reducing wastage, and optimizing supply chain workflows.

Solution Offered To Kryolan Professional Make-up by LOGIC ERP Company

Kryolan partnered with LOGIC ERP to address growing operational complexities by implementing end-to-end ERP software. By automating processes such as order management, billing, and production with QC, LOGIC ERP empowered Kryolan with a fully integrated and customized ERP software that helped them achieve greater efficiency, faster decision-making, and seamless coordination across departments, strengthening its position as a global leader in professional makeup and skincare manufacturing.

1. Centralized Real-Time Inventory Tracking

LOGIC ERP enabled real-time inventory visibility across the head office, warehouses, production units, and all 9 retail stores. It helped Kryolan maintain accurate stock levels, avoid shortages or overstocking, and ensure efficient product movement across its entire supply chain.

2. POS Integration for Seamless Retail Operations

Kryolan stores are now equipped with a smart POS system integrated with the central retail ERP software. This process ensured fast billing, synchronized transactions, and unified data flow between retail outlets and head office, improving sales efficiency and customer satisfaction.

3. Centralized Sales, Purchase, and Stock Movement Management

The FMCG and Cosmetics Distribution Module in LOGIC ERP distribution software streamlined all sales and purchase operations. Offering a centralized view of stock transfers, sales performance, and purchase analytics, our cosmetics ERP software enabled better decision-making and demand planning.

4. Advanced Production Management

LOGIC ERP manufacturing software automated Kryolan’s production planning and manufacturing workflows with features like Bill of Materials (BOM), work orders and process execution which enhanced traceability, optimized material consumption, and ensured efficient resource utilization across production lines.

5. Integrated Quality Control at Every Stage

Quality is the core of the cosmetics and skincare manufacturing industry. LOGIC ERP introduced a Quality Control (QC) module integrated at every production stage from raw material inspection to in-process checks and final product testing, ensuring compliance with international quality standards. Integrated deeply into the production workflow, this module ensures that each product meets the highest quality standards before reaching the market.

QC Checkpoints at All Stages

- Raw Material Inspection before batch approval

- In-Process Quality Checks at key manufacturing stages

- Final Batch Testing for Finished Goods

Parameter-Based Quality Testing

- Each product line is defined with custom QC parameters such as pH level, texture, color match, and consistency.

- Test results are recorded for every batch, ensuring traceability and adherence to Kryolan’s global quality standards.

6. Barcode and Batch Tracking for Traceability

The implementation of barcode-enabled batch tracking gave Kryolan complete control over product traceability which improved regulatory compliance, expiration tracking, and helped in monitoring material movement with full transparency.

Every batch is linked with its QC test results, approval status, and barcode for complete traceability and regulatory compliance. Historical QC data enables easy audit readiness and ensures transparency throughout the production cycle.

7. Approval Workflow for Quality Control

LOGIC ERP implemented a role-based QC approval workflow to ensure complete control over the cosmetics manufacturing process. Each batch undergoes mandatory quality verification before clearance, with automatic alerts generated for any non-compliance or deviation. This guarantees that only batches meeting all defined quality parameters proceed to the packaging and dispatch stages, ensuring consistent product quality and regulatory compliance.

8. Unified Dashboards and Real-Time Reporting

With centralized dashboards and analytical reporting tools, Kryolan’s team gained real-time insights into sales performance, production efficiency, and inventory movement. This visibility empowered faster decisions and enhanced operational control for the head office and retail management team.

Industry-Specific ERP Modules Developed and Deployed

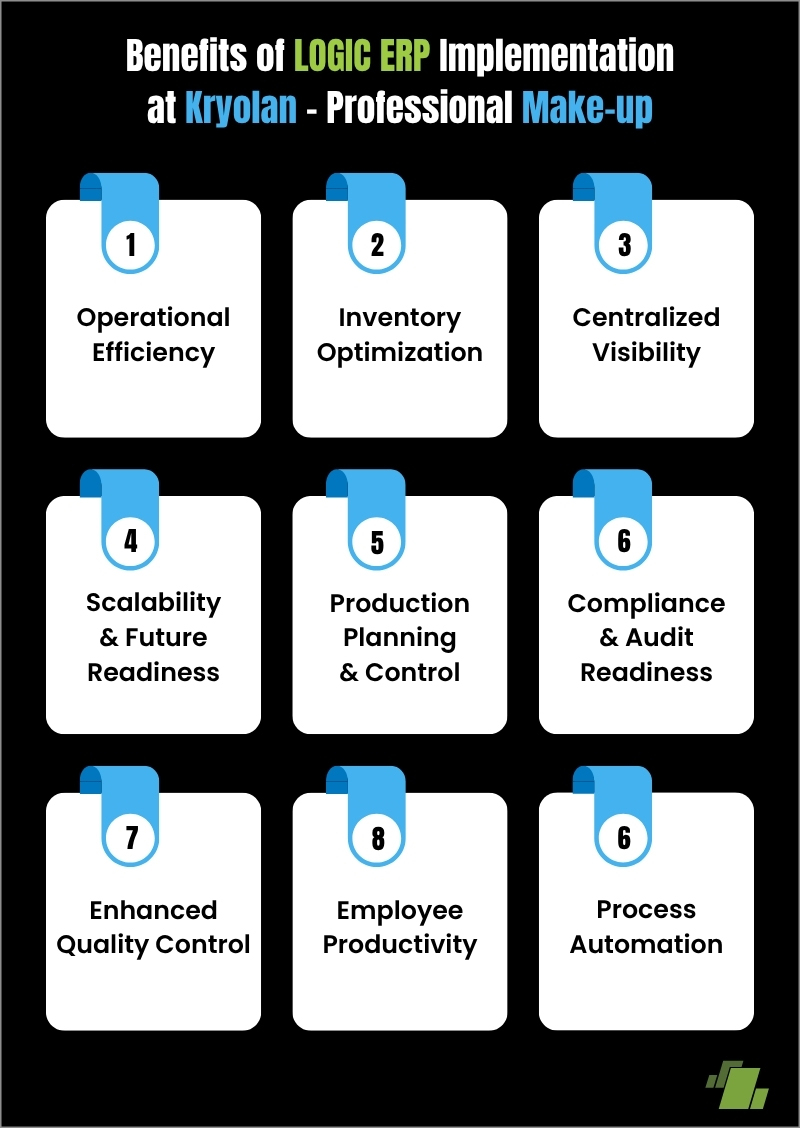

Benefits of LOGIC ERP Implementation at Kryolan – Professional Make-up

The implementation of LOGIC ERP brought transformative value to Kryolan Cosmetics’ centralized operations in Chennai and its 9 retail stores across India. By integrating all business operations, from production and quality control to inventory & sales. LOGIC ERP cosmetic ERP software delivered measurable and strategic benefits across the organization.

Operational Efficiency

- LOGIC ERP automated manual tasks across production, inventory, billing, and approvals, ensuring smooth operations at every level.

- The cosmetics ERP software streamlined coordination between retail, distribution, and manufacturing departments through a unified system.

- Faster task execution with minimal errors and reduced rework boosted overall efficiency.

Enhanced Quality Control

- The beauty products ERP software enabled batch-wise tracking and approval workflows for every stage of production.

- Defined QC parameters helped maintain consistent product quality across skincare and cosmetic lines.

- Real-time alerts and test recording ensured full traceability and compliance.

Centralized Visibility

- LOGIC ERP provided real-time visibility into stock, sales, and production across all 9 retail stores, warehouses, and the manufacturing unit.

- Unified dashboards empowered the Head Office to monitor store-wise performance, sales trends, and profitability.

- Accurate and centralized data improved planning, decision-making, and control.

Inventory Optimization

- With advanced skincare ERP software, stock discrepancies and dead stock were minimized.

- Real-time tracking of raw material consumption and wastage optimized resources.

- Improved forecasting and automated replenishment ensured each retail store stayed well-stocked.

Production Planning & Control

- LOGIC ERP simplified production management through BOM (Bill of Materials) and work order tracking.

- Process-wise costing helped maintain control over margins in manufacturing operations.

- System-driven planning shortened production cycles and improved output quality.

Compliance & Audit Readiness

- Detailed historical batch and QC reports made audits effortless and transparent.

- The system enabled full product traceability from raw materials to final retail sale.

Scalability & Future Readiness

- LOGIC ERP’s cosmetic and beauty ERP software is scalable, supporting business expansion into new cities, channels, or product lines.

- Modular structure allows easy integration with upcoming tools or technologies.

- Strong analytics and reporting capabilities enable strategic planning and growth.

Employee Productivity

- Role-based access and automation reduced manual entries and spreadsheet dependency.

- Teams now focus more on insights, analysis, and growth initiatives.

- Enhanced collaboration across retail, distribution, and manufacturing units increased overall productivity.

Implementing Cosmetics ERP Software by LOGIC ERP, Kryolan Cosmetics achieved complete control, visibility, and automation across its retail, manufacturing, and distribution operations. The system empowered the brand to improve efficiency, quality, compliance, and scalability, creating a strong foundation for sustained growth in the beauty and skincare industry.

How Can LOGIC ERP Help Your Cosmetics Business with Advanced Software Implementation?

LOGIC ERP empowers cosmetics, skincare, and beauty product businesses with an end-to-end digital transformation platform to streamline retail, distribution, and manufacturing operations.

By integrating real-time inventory management, automated billing, multi-warehouse control, and data-driven decision-making, LOGIC ERP ensures seamless coordination across the entire FMCG distribution network. From production planning and procurement to sales order management and supply chain visibility, every process becomes faster, more accurate, and fully connected.

With LOGIC ERP for Cosmetics and Skincare Industry, Kryolan gained complete control over their business ecosystem, improving efficiency, reducing costs, and accelerating growth. Whether you operate in cosmetics manufacturing, retail, or FMCG distribution, LOGIC ERP provides the scalability and intelligence needed to stay competitive in the ever-evolving beauty industry.

Why Choose LOGIC ERP For Your Cosmetics Business?

LOGIC ERP is one of the most trusted cosmetics ERP software solutions providers in India. Established in 1993, we have been driving the business growth of top cosmetics brands in the world: Birla Cosmetics, Colorbar, Forever 52, KT Professional, and many more with beauty products ERP software implementation.

What makes us unique in the world of ERP:

- 30+ Years of ERP Excellence

- 200+ Experienced ERP Experts

- Personalized ERP Training Just for You

- Fast, Easy, & Stress-Free Implementation

- Quick & Easy Personalization & Deployment

- Flexible Solutions: On-Premise or On-Cloud

- Strong Domain Knowhow & Success Stories

- Digital Ready ERP with 3rd Party Plug-in & API

Conclusion

The LOGIC ERP x Kryolan collaboration demonstrates how an advanced ERP software for cosmetics, skincare, and FMCG distribution can revolutionize retail, manufacturing, and supply chain operations. With real-time inventory visibility, automated order processing, and integrated production and distribution management, Kryolan achieved complete process automation and operational excellence.

Our cosmetic ERP solution streamlined multi-warehouse control, optimized sales and procurement, and improved overall efficiency across its FMCG network. Today, Kryolan stands as a leading example of how LOGIC ERP for cosmetics, skincare products retail, manufacturing and FMCG distribution businesses enables brands to scale globally, enhance profitability, and ensure sustainable growth in a highly competitive market.

Get started today! Call +91-7341141176 or email us at sales@logicerp.com to schedule your free demo of ERP Software for the Cosmetics and Skincare Industry, and take the first step towards operational excellence with LOGIC ERP!